Studio RAP is an architectural design company with a difference. The Rotterdam-based studio works with robots to challenge conventional approaches to architecture and construction. From its workshop in Rotterdam’s RDM Innovation Dock, Studio RAP’s team of architects, designers, roboticists, programmers, and researchers combine computational design with innovative digital fabrication methods. In 2016, Studio Rap completed the Netherlands’ first robotically fabricated building, designing a large vault made up of 225 unique wooden panels with an eight-meter (approx. 26 feet) span. More recently, the studio completed an unusual project on Amsterdam’s P.C. Hooftstraat. Named Ceramic House, the project utilized Studio RAP’s own custom-built 3D printing technology to create a ceramic facade for a boutique shopfront on the high-end shopping street.

Algorithmic design

The design for Ceramic House seamlessly blends tradition and innovation to craft a new architectural expression. Using in-house digital design algorithms, the project explores a fresh way of thinking about the decorative qualities and design vocabulary of glazed ceramics. It’s a method of working that Lucas ter Hall, Studio RAP’s co-founder and a specialist in parametric design and robotic production, is passionate about. “We have developed an innovative algorithm that encompasses specific parameters to exert precise control over the design outcome. Rather than manually creating each ceramic tile, we influence the algorithm responsible for generating the tile's shape,” says Ter Hall. “These parameters encompass various aspects such as the amplitude of the tile waves, the transition effects, and the texture. Through meticulous manipulation of these factors, our algorithm crafts the unique and visually appealing tile designs.”

A 3D printed ceramic facade inspired by the art of knitwear

The organic, undulating quality of the Ceramic House facade was inspired by textiles and knitting. “To fulfill our client’s brief, we wanted to design and realize something truly new, that would inspire people — a facade with an unprecedented richness in ornamentation and detailing, crafted in such a way that it fits with the existing historic architecture of Amsterdam’s famous P.C. Hooftstraat. The question was how do we do this?” says Ter Hall. “At that time, we were already experimenting with the 3D printing of ceramic tiles for another Studio RAP project called New Delft Blue. Amsterdam’s historic city center and the nearby Rijksmuseum [with its celebrated and diverse ceramic collection], have a notable legacy in ceramic architecture and art. We arrived at the idea of designing a facade that was completely clad in 3D printed ceramic tiles, in a manner that amplifies the identity of a high-end fashion store. Ceramic House was born: a 3D printed ceramic facade inspired by the art of knitwear.” Each ceramic tile was designed and individually printed in a way that recalls the idea of textiles, with its embroidery, folds, and texture.

Digital fabrication with a human touch

Studio RAP employs its own large-scale 3D printing technology to accomplish highly distinctive and algorithmically designed details. The approach underscores the studio’s commitment to pushing the many established boundaries of architectural design. Its unique digital fabrication process has been developed over the course of several years and includes the creation of advanced robotic systems. These robots are to all intents and purposes an intrinsic part of the team, diligently working to craft complex ceramic designs. At Studio RAP, artisanship, computational design, and innovative digital fabrication are all part and parcel of the studio’s modus operandi. “The artisanal touch remains integral even in the realm of robotic printing,” says Ter Hall. “The glazing and handling processes are carried out by skilled hands, highlighting the human element of our craft. Moreover, a substantial amount of effort is invested in crafting the intricate code that guides the robot in its interaction with the clay, thereby determining its behavior during the printing process.”

At Studio RAP, the robot is not viewed as merely a solution to achieving the mass production of ceramic tiles. Rather, Ter Hall very much considers the robot to be “a sophisticated tool that enhances the studio’s ability to sculpt extraordinary panels.” He continues: “It complements the artisan's touch, allowing us to achieve unparalleled creativity and precision in our work.”

Ceramic House tile production (by Studio RAP):

An expressive 3D printed ceramic facade

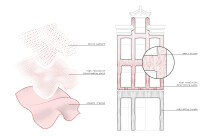

At street level, the Ceramic House facade is clad in larger 3D printed ceramic tiles — each one measures approximately 40 x 20 centimeters. The tiles are glazed by Koninklijke Tichelaar (Royal Tichelaar) in pearl white with a subtle shade of yellow. (Koninklijke Tichelaar, the oldest ceramics company in the Netherlands, collaborated with Studio RAP on the Ceramic House project.) “These tiles are designed to be visually expressive at eye level — they seamlessly transition to a flush alignment as they meet the ground, creating a harmonious and detailed aesthetic,” says Ter Hall. The wave-like properties of the facade change and morph as the viewer approaches from different angles, revealing unseen elements.

In contrast, on the building’s higher floors, the facade is clad in 3D printed bricks glazed in three different shades of red. The bricks are “laid” alongside the original masonry cross bond and have an abstract ornamentation that fades (becomes smoother) as they move higher. The bricks are placed in laser-cut stainless steel cassettes, alluding to the original flushes. Both the bricks and the larger ceramic tiles are printed in the same way (Ter Hall notes that the clay mixture “is classified”), although the bricks have a different type of glaze.

Studio RAP’s aspiration for Ceramic House is that of a luxury boutique, one that is in harmony with its historic setting while also standing apart. The approach is particularly thoughtful, aligning both traditional and contemporary architecture: “our design replicates the original facade’s silhouette and maintains the street’s tripartite structure,” says Ter Hall. “In this way, the plinth, midsection, and crown sync with those along the street.”

3D printing: the designer’s "superpower"

As a material, ceramic is in the main hard-wearing, highly stable, resistant to corrosion, and weather resistant. Ceramic has a long history and in effect, lasts for a long time. Made from clay, the ceramic facade provides optimum thermal, fire, and sound insulation. In the case of Ceramic House, by using digital design algorithms and 3D printing, it does all of this with great panache.

“Our vision is one that enriches the world with a new architectural language through the power of emerging digital technologies, thus innovating the way in which the world is imagined, built, and experienced,” says Ter Hall. He describes 3D printing techniques as giving “superpowers” to designers, enabling them to create a new language and means of expression.

In practical terms, 3D printing provides the team at Studio RAP with a greater level of autonomy, control, precision, and flexibility (when compared with traditional construction techniques). The studio’s work is challenging architecture through the power of computational design combined with innovative digital fabrication, while striving to maintain the time-honored values of artisanship. “Ceramic House is an achievement that stems from years of dedicated research, as demonstrated by our in-house 3D-printing technology and advanced robotic systems,” says Ter Hall. “I would add that collaborating with Koninklijke Tichelaar on the project lends an intriguing dynamic to our work, by blending modern technology with traditional expertise.”